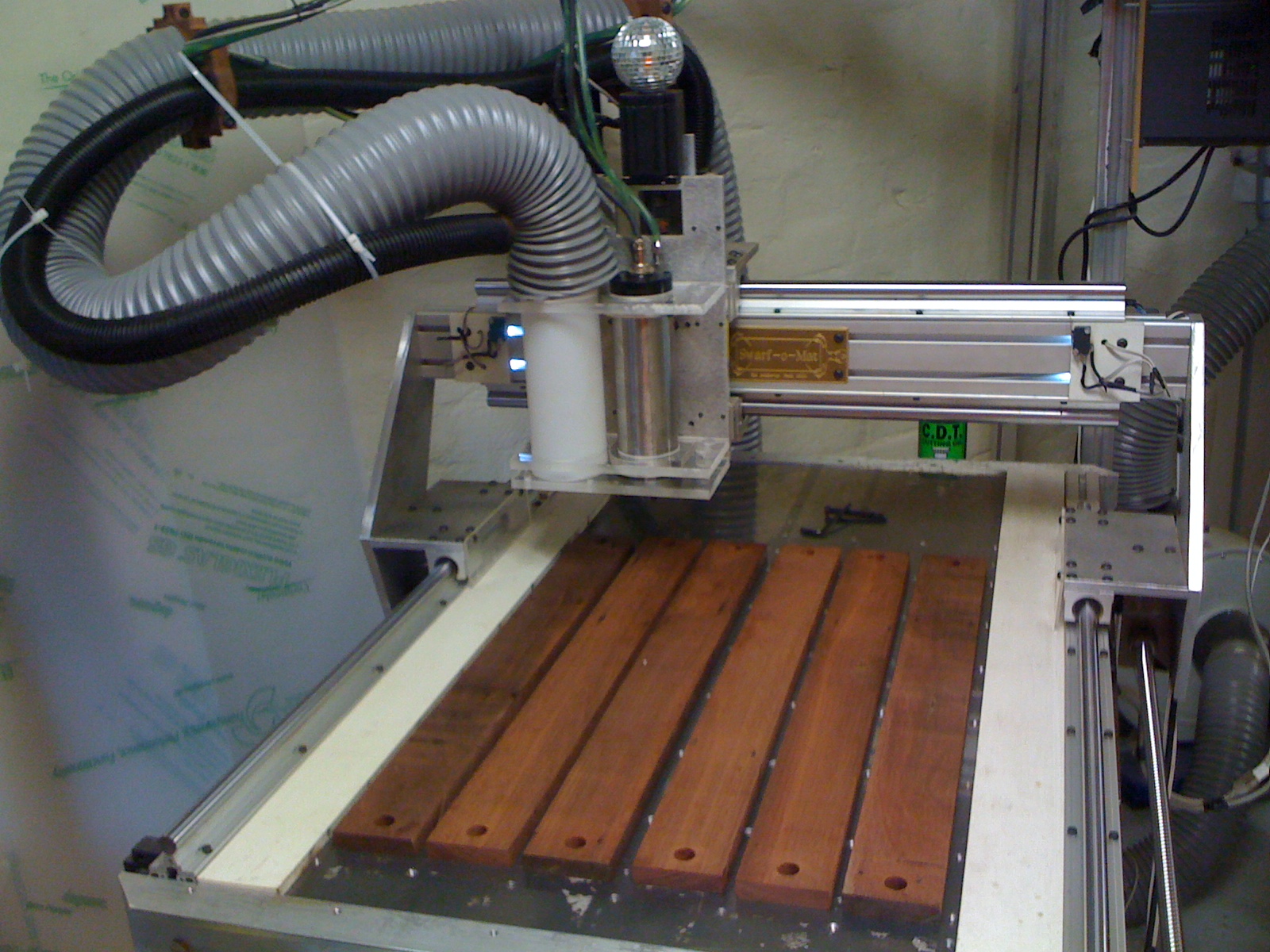

¶ Swarf-O-Mat CNC Router

You need to be trained (and pass a test) before using our CNC router.

CNC router training is currently only available to members.

Only current, authorized trainers can deliver router training.

¶ Summary

The Swarf-O-Mat is a CNC router that can machine wood, plastics and soft metals. Swarf-O-Mat was built by skot in 2010, back before AliExpress was a thing, and donated to the Artifactory. There is a small selection of Artifactory-owned tooling available, but regular users will want to purchase their own tooling (the charge for use is lower if users supply their own tooling).

The Swarf-O-Mat is a CNC router that can machine wood, plastics and soft metals. Swarf-O-Mat was built by skot in 2010, back before AliExpress was a thing, and donated to the Artifactory. There is a small selection of Artifactory-owned tooling available, but regular users will want to purchase their own tooling (the charge for use is lower if users supply their own tooling).

:!: As with all CNC machines, learning to use Swarf-O-Mat safely (for the user and the machine) requires a significant investment of time. Without appropriate training, the machine has the potential to be very dangerous. As such, it is 'gated' and you may not use it until you have been trained.

¶ Hazards

¶ Trainers

| Trainers | Availability |

|---|---|

| Fletcher Boyd | #training-and-inductions on Slack |

| Iain Graham | Unavailable |

| Ben Connor | By request (Slack) |

¶ Operators

An up to date list of operators can be found here

¶ Tool Usage Fees

Refer to Tool Usage Fees.

¶ Swarf-o-Mat Reference

Note: These figures are conservative. Have cut pine successfully at 0.2mm per tooth, 60% stepover with 6mm end-mill. - Penny W Apr/2024

| Material | VFD Setting | Feed Rate (6mm Tool) | Pass Depth (mm) | Notes |

|---|---|---|---|---|

| Aluminium | 400 | 200mm/min | 0.25 | Swarf will re-weld to sides of channels - keep job clean |

| HDPE | 300 | 1200mm/min | 3 | Cuts like butter |

| Perspex / Acrylic | 300 | 600mm/min | 2 | Grind the plastic, don't melt it - take it slower than wood |

| Jarrah | 400 | 800mm/min | 2 | Jarrah gets even HARDER if burnt |

| Pine | 400 | 1300mm/min | 3 | Forgiving & easy |

| MDF | 400 | 1300mm/min | 3 | Easy to cut, but dust is toxic |

¶ Specifications

| Parameter | |

|---|---|

| X Axis Range | 600 |

| Y Axis Range | 420 |

| Z Axis Range | 70 |

| Spindle max RPM | 24,000 rpm |

| Collet | ER11 |

| Driver Software | Mach3 |

| Full Swarf-O-Mat Area | 600mm x 460mm x 70mm (minus buffer) |

| Maximum Dimensions of Any job | 580mm x 440mm x 60mm |

| Post processor | Mach 3 Arcs mm |

¶ Approved Materials

You can not use a lot of things, if it's not listed here and/or you're not sure ASK!

- Soft wood

- MDF

- acrylic

- HDPE

- hard wood

- aluminium

¶ Swarf-O-Mat Checklist

- Computer, controller and chiller powered on

- Check table is clear and no mechanical obstructions to movement

- Reference (home) all axes. X axis should self-square when referenced

- Switch on soft limits (not compulsory, but recommended)

- Clamp job tightly with spoil board underneath

- Check clamps and biscuits clear of moving gantry

- Install collet into collet nut. IMPORTANT- this must be done before the tool is installed in the collet.

- Install cutting tool in correct-sized collet and tighten with spanners

- Load g-code and check the tool path appears correct

- Move to desired zero locations and x and y axes

- Optional: zero z axis with clearance above the workpiece and do a dry run 'cutting air'

- Move to the desired zero location and zero the z axis

- Move clear of the workpiece

- Check cooling water is flowing

- Turn on room fan and dust extractor

- Turn on PPE light

- Check all present are wearing safety gear. Eye protection is mandatory. Hearing protection is recommended.

- If your G-code does not include spindle control, set the spindle speed and turn the spindle on

- Begin the job

- Turn off spindle

- Remove job and spoilboard

- Pack away clamps, biscuits and tools

- Clean up using the vacuum cleaner

- Log out

- Power off computer, controller and chiller

- Report any problems to #tools_and_fabrication.

¶ Instructions for Use

Very important condition of use: Use Swarf-o-mat with caution!

This is a FRAGILE and awesome bit of equipment -- RESPECT IT, BE CAREFUL!

If you're not 100% certain about what you're doing, DON'T! Get advice and take care.

¶ 1) Know what you want to make/do

If you're here, hopefully you already have plans.

You can:

- cut

- engrave

- carve (to a limited extent)

¶ 2) Plan and draw your project in VCarve

VCarve is the supported software for use with swarf-o-mat.

This software is installed on the computers available in the computer room in the space.

Artifactory members can make a folder on the network that can be accessed by swarf-o-mat.

Detailed instruction are provided on Vcarve Instructions page.

¶ 3) Cut material with swarf-o-mat

USE THE MACHINE WITH EXTREME CARE

If you are not sure what you are doing: DON'T DO IT -- get help and advice from one of the friendly swarf-o-mat operators.

Detailed instructions are provided on Swarf-O-Mat Usage Instructions page.

¶ Quick and dirty notes on spindle speed control

As of 20/6/21 Swarf-o-mat is configured for software control of spindle speed (including start/stop). Spindle speed can be set in three ways:

¶ Spindle control through Mach3 UI

The spindle speed can be set through the Mach3 UI, in the lower right corner of the main (Program Run) screen:

¶ Spindle control in g-code

The spindle can be started or stopped, or speed controlled, with g-code commands, either entered through the Mach3 UI on the MDI page or embedded in your program:

- M3 starts the spindle

- M5 stops the spindle

- Sx sets the speed to x RPM

Once set, the spindle speed can be overridden through the Mach 3 UI

¶ Spindle control through VFD touch pad

Should you want to return Swarfomat to spindle control through the touchpad, please change only the VFD settings. Do not mess with the Mach 3 setup. The relevant VFD settings are:

- PD001, which determines the source of run commands. 0 denotes control from the touchpad, 1 denotes control via digital input.

- PD002, which determines the source of speed commands. 0 denotes control from the touchpad, 1 denotes control via 0-10v analog input.

Instructions on how to change the settings through the touchpad are in the .

¶ Documentation

| Document | Notes |

|---|---|

| Reference for the Huanyang variable-frequency drive | |

| Reference for the CNCDrive UC300ETH controller | |

| Reference for the UCBB breakout board | |

| Reference for the z-axis driver | |

| Reference for the x- and y-axis drivers | |

| Reference for the safety relay | |

| Installation and user guide for Mach3 Mill | |

| Chiller | Instruction manual for the spindle cooler |

¶ Notes

Details of Swarfomat's configuration are available on the maintenance information page.

Information relating to the original build is available on the original Project Page.